|

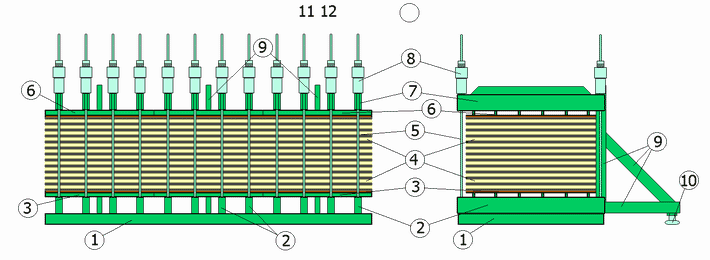

1. MANUAL SCREW PRESS PSP-1500/03

Legend:

- All-welded base of the press

- Lower beams for press made of rectangular steel profile

- Lower pressing reinforcement plates

- Packet of sandwich panels for pressing

- Coupler screws with trapeziform thread

- Upper pressing reinforcement plates (made of 3 parts)

- Upper beams for press made of rectangular steel profile

- Dynamometrical clips (with marks for definition of required pressure)

- Vertical beam for an accurate orientation of sandwich panels in a packet for pressing

For provision of accuracy of “mirror” of sandwich panel lower and upper press beams are stressed with the specified loading before welding.

|

Coupler screws with lower hook end (5) and elements of dynamometrical clips (8) |

|

|

Manual screw press PSP-1500/03 |

Manual screw press PSP-1500/03 on elevator |

Technical characteristics:

| Maximal pressure |

0,3 kg/sq.sm. |

Inaccuracy of pressure definition |

0,03 kg/sq.sm. |

Maximal plate’s size |

1500х3000 mm |

“Mirror” inaccuracy |

< 0,5 mm/1000 mm |

Time of pressurization (with recommended glue) |

2-4 hours |

Maximal packet thickness |

1200 mm |

Minimal packet thickness |

10 mm |

Equipment production period |

4 weeks |

Price * EUR, EXW, Oborniki Poland. Delivery and custom clearance in Moscow - * EUR

2. HYDRAULIC PRESS PG/1500-07 ("VAIMA")

Specification:

| Weel base |

1 pcs. |

| Moving table |

1 pcs. |

| Covering plates |

3 pcs. |

| Side beam |

12 pcs. |

| Basic (orientation) beam |

3 pcs. |

| Crossbeam |

6 pcs. |

| "Fingers" |

24 pcs. |

| Jack |

1 pcs. |

| Pedal |

1 pcs. |

| Valve handle |

1 pcs. |

| Carrier handle |

1 pcs. |

Technical characteristics:

| Length |

3100 mm |

| Width |

1600 mm |

| Plates thickness |

from 8 mm |

| Maximal pressure |

up to 2 t/sq.m. |

| Maximal size of plates (PVC sandwich panels) |

1500мм х 3000 mm

(at customer request) |

| Maximal sandwich panels |

1200 mm |

| “Mirror” inaccuracy |

< 0,5 mm/1000 mm |

Several presses are required for normal operation.

Price of 1 press - * rubles EXW, Moscow, Russia

The main advantage of the press is absence of necessity of bolt screwing for pressing (reduction timetable). The pressure is made by inflation with pedal-jack. It is possible to make the press for sandwich panel up to 2000mm in width. At customer request it is possible to provide a system of precise adjustment of parallelism of upper and lower plates of the press with the help of adjustment screws.

|

Scheme of the press |

|

Press (width 1500mm) |

|

Press (width 2000mm) |

3. MACHINE FOR ASSEMBLY AND ROLLING OF SANDWICH PANELS

The machine has a roll-table for manual assembly of sandwich panels and 2 roll for manual preliminary pressing of sandwich panels (for moving away air and excess glue).

Technical characteristics:

| Length |

3000 mm |

| Width |

1600 mm |

| Roll-table height |

760 mm |

| Weight |

150 kg |

Price: * USD, EXW, Poland, Oborniki.

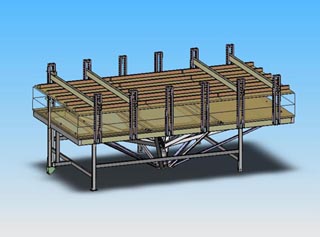

4. MACHINE FOR FORMING OF A PACKET OF ASSEMBLED SANDWICH PANELS (ELEVATOR).

We offer manual elevator for putting into press thin sandwich panels (thickness 10-32mm). It is made of steel profiled beams with manual actuator of lifting with lower press plate.

The elevator sets the lower press plate directly on the level of roll-table (glueing table). Every time a new assembled sandwich panel is put on the elevator it goes down on the thickness of the panel with the help of manual actuator. It prevents flexure of sandwich panel and prevent a possible shift of PVC sheet. Base vertical beams provide accurate sandwich panel packet forming. A loader or a beam-crane is used for putting the packet of sandwich panels into press. You can also order a special trolley-elevator for lifting and transportation of sandwich panel packet or even the press with the packet.

Trolley price - * USD, EXW- Poland, Oborniki.

Legend:

- beam with lifting screw,

- manual screw ,

- basing beams ,

- lower press plate.

Price (of the lifting table): * USD

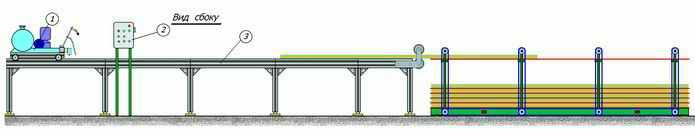

5. GLUEING MACHINE SNK-4.1500w.04 (SNK-4.2000w.04)

Technical characteristics:

| Length |

4000 mm |

| Maximal width of glueing |

1500(2000) mm |

| Value of glue tank |

100 L |

| Power consumption of glueing carriage actuator |

0,55 kW |

| Pump power consumption |

1,2 kW |

| Pump productivity |

upto 3 L/min |

| Pump maximal pressure |

upto 8 atm. |

| Length of glueing |

3 m |

| Speed of the glueing carriage (forward) |

5 m/min |

| Time of glueing carriage run (forward) |

(3m : 5 m/min) = 40 sec. |

| Speed of the glueing carriage (backward) |

10 m/min |

| Time of glueing carriage run (backward) |

(3 m : 10 m/min) = 20 sec. |

| Quantity of glue |

100-350 gr/sq.m. |

| Rolls for preliminary pressing of sandwich panel |

2 pcs. |

Production period- 1,5 months.

Price: roll-table length 4,0 m - *USD, glueing machine 3,0 m - * USD.

Total p rice : * USD EXW-Oborniki, Poland.

Terms of payment :

- prepayment before production - 30%

- prepayment 1 month after production start - 30%

- payment before shipment - 35%

- final payment after mounting - 5%

Technical description of glueing machine SNK-4.1500w.04 (SNK-4.2000w.04)

The gluing machine is a roll-table (modular type) with a gluing carriage with a glue tank. The length of one module of roll-table is 1 meter. So the total length of the table is discrete to 1 meter. The machine is made of special aluminum profile system ”ARI metal”. 2 rolls are installed on a machine for preliminary pressing of sandwich panels. Maximal gluing width – 1500(2000)mm. The width could be changed closing of some nozzles (glue is not spraying with high pressure but streaming through nozzles). Each nozzle could be closed. A simple single-component glue is used (like for manual gluing). Number of nozzles – 198pcs, diameter – 1.2mm. Total section of all nozzles – 214sq.mm. (2.1 sq.sm). – for gluing machine SNK-4.1500w.04. Carriage speed and a speed of glue outflow could be changed (50-500gr/sq.m). The machine has its control unit (length of gluing, carriage speed, glue quantity could be changed).

Gluing carriage is equipped with device for water spraying during backward run (water is a catalyst). So the carriage is equipped with water tank, water pump, spraying system and additional control on the central control unit. The price of water spraying device is 2200USD (included in total price) – it could be excluded from equipment set.

Modification of gluing machine.

New modification has advanced gluing system with new nozzles with closing mechanism (each nozzle has a closing needle, all needles are driven by the general pneumatic system and are automatically controlled).

The main advantages of new gluing system:

- Nozzles are always clean (with no glue) and are always ready for gluing

- A standard every-day and total every-week cleaning are not required

- Time and glue economy

Disadvantage - higher price. Modification of gluing machine – is a complex device, that requires high-accuracy production. Needle-valve has to be make with high accuracy. A part of each valve is absolutely isolated from atmosphere with special gasket put is isolating oil cover. New gluing device provides high reliability and easy service.

Price of additional elements –* USD

6. THERMO-PRESS

For process autoimmunization we offer the roll thermo-press modular type 4 meters in length (length of each module – 1 m) for thermo-pressing of sandwich panels (instead of screw press). Speed, temperature and pressure are changeable and optimized for the best and quick pressing. Thermo-press is adjusted depending on sandwich panels thickness. Rolls of thermo-press are optimized for absolutely perfect pressing (with no waves). For process autoimmunization we offer the roll thermo-press modular type 4 meters in length (length of each module – 1 m) for thermo-pressing of sandwich panels (instead of screw press). Speed, temperature and pressure are changeable and optimized for the best and quick pressing. Thermo-press is adjusted depending on sandwich panels thickness. Rolls of thermo-press are optimized for absolutely perfect pressing (with no waves).

All mechanism is put in thermo-isolating tunnel (made of sandwich panels) that has input and output gates. The tunnel is quickly dismountable. Air-heating system is circle. The press has its own central control unit (for speed, temperature and pressing control). Input and output is automatic. Modular roller tables (delivery table and receiving table) are used for input and output of sandwich panels.

7. AUXILIARY EQUIPMENT

- Foam plastic cutting machine (cutting to sheets)

- Sandwich panel packet packing machine

- Protective film covering device

- Side-cutting machine

8. SEMI-AUTOMATIC TECHNOLOGY OF PVC SANDWICH PANEL PRODUCTION

Required equipment .

- Gluing machine with preliminary pressing rolls - * USD

- Trolley-elevator - * USD

- Special steel sheets for putting between sandwish panels in a packet (advisable) 160 pcs. - * EUR

- Packet presses 8 pcs. - * EUR

Equipment set price - * EUR

The production could be started without special steel sheets and only with 1 press - minamal equipment set price- * EUR

Production characteristics.

- Productivity - nearly 160 sandwich panels per 8-hour shift (for sandwich panles size 3000х1500х10mm).

- Staff - 3 persons.

- Production area - from 200 sq.m.

Brief description of technology.

Gluing process is automatic (on roll-table). Putting of PVC-sheets and prepared foam plastic sheets – manual (on roll-table). Prepared sandwich-panel is input into rolls for preliminary pressing (to avoid air in panel and for better gluing). Then the panel is put in a packet of sandwich panels prepared for final pressing. Pressing is manual in screw press (or automatic in thermo-press – option). The packet of pressing panels is transferred to stock for 4-hours delay for pressing.

At your request we can send you a calculation of productivity for required equipment. Please contact us.

9. SPECIAL GLUE FOR PVC SANDWICH PANELS

For the gluing process of PVC sandwich panels we recommend you specially developed single-component polyurethane glue “ATK-3” for PVC. You can also use universal glue ATK-3. Regarding glue delivery please call us.

10. EXTRUDED CELLULAR POLYSTYRENE (FOAM PLASTIC) FOR PVC SANDWICH PANEL

For filling PVC sandwich panel an extruded cellular polystyrene (foam plastic) could be used (manufacturer: “Penopleks”, Saint-Petersberg). Foam plastic is produced in sheets 1500*3000mm in size (thickness – 8mm, 24mm and up to 100mm). You can order Penopleks sheets with cutters grooves for air removal. Regarding delivery please call to Igor Sysoev +7(812)329-54-11, e-mail: i.sysoev@penoplex.ru.

11. PVC SANDWICH PANEL DESCRIPTION

PVC sandwich panel is a three-layered panel (PVC sheet + foam plastic + PVC sheet), produced by gluing and pressing. Size: (10+)*1500*300mm.

First layer – hard PVC sheet with decorative surface (glossy or lusterless) 1mm (1.5mm) in thickness. Second layer - filling material – foam plastic.

Third layer - hard PVC sheet 1mm (1.5mm) in thickness.

PVC sandwich panel has high heat and noise-insulated characteristics.

12. PVC SANDWICH PANELS FIELD OF USE

- Office deviders

- PVC doors

- Interior furnishing

- Exterior and interior finishing elements

- Isothermal construstions

Two-sided PVC sandwich panel is an ideal material for building. Elements made of PVC sandwich panels is has no disadvantages in comparison with molded plastic 9mm in thickness but has big advantages: very high heat and noise-insulated characteristics and lower price.

13. APPROXIMATE PVC SANDWICH PANEL PRICE

| Thicknessl, mm |

Length and width, mm |

Cover and filling material |

Price USD,

(less then 10 pcs.) |

Price USD,

(10-50 pcs.) |

Price USD,

(more then 10 pcs.) |

9 |

3000х1500 |

lusterless PVC, FP, EFP |

60 |

56 |

54 |

9 |

3000х1500 |

glossy PVC, FP, EFP |

60 |

56 |

54 |

24 |

3000х1500 |

lusterless PVC, FP, EFP |

72 |

70 |

68 |

24 |

3000х1500 |

glossy PVC, FP, EFP |

72 |

70 |

68 |

PVC - polyvinyl chloride (white, 1mm)

FP - polystyrene (1mm)

EFP - extrusion polystyrene

PVC sheet is covered with transparent protective film, which is removing after panel mounting

Do you have any questions? Do not hesitate to call us! |